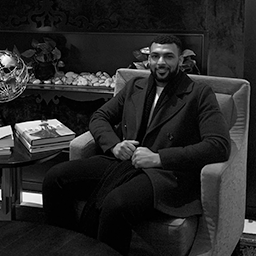

Rasan Chandra

Continuous Improvement Manager

British Sugar

Content added September 2019. Rasan has since left the business.

Rasan’s career in sugar began while still at university when he joined AB Sugar on a one-year Mechanical Engineering placement in 2014. Following this, he returned to the University of Sheffield to complete his Masters degree before starting on the graduate programme with British Sugar, one of AB Sugar’s businesses. He comments:

“My placement year at AB Sugar was an excellent experience; it helped me to build a network which in turn allowed me to secure my place on the graduate programme at the end of my studies. I also got involved in several additional areas related to my degree while at University. For example I was an International Engineering Ambassador which involved talking to prospective students and current students to promote my degree course. I was given lots of responsibility in this role which I really enjoyed, and the highlight was presenting to the university faculty. Promoting careers in Engineering is something that’s really important to me too.”

“Be ambitious and acquire as much as experience as possible”

Upon joining British Sugar at the Bury St Edmunds factory in Suffolk to start his graduate programme, Rasan has accelerated and spent time in several factory departments. He explains:

“I started out in the Shift Team at the factory where I learnt the process of making sugar from sugar beet, an arable crop grown across the East of England. Following this in 2017, I became Shift Performance Manager, responsible for a team of eight people. At the end of 2017, I moved to the Wissington factory into the Maintenance Resource Planning team, where I was responsible for managing a technical team and organising proactive maintenance activities to ensure the factory continues efficiently to process sugar beet. More recently I was in the Combined Heat and Power (CHP) team, managing contractors during an outage for the energy plant and delivering projects to make processes even better.”

Rasan has since moved to the Newark factory to take up the role of Continuous Improvement Manager, delivering improvement projects and identifying future efficiency projects for the factory. He is looking forward to continuing to learn all about sugar and the industry as well as taking up every opportunity coming his way.

“I’ve tried to take all the opportunities thrown at me so far, as in the factory no day is the same so you’re always learning. The variety of roles and placements over the past two years has been great and have given me a solid foundation to continue developing into the future. I’ve been challenged a lot and pushed out of my comfort zone, but I think this is the best way to learn – from opportunities. The people I’ve worked with have been encouraging and have provided support when needed, but I’ll also continue striving for more."

Notes to editors:

Rasan was nominated in the 'Rising Star' Award at the 2019 Food and Drink Federation Awards

Share this case study:

Case studies

More